About us

Your supplier of professional transport solutions

About us

Tyllis Oy Ab designs and manufactures transport technology solutions for professionals. Our head office and factory are located in Kokkola, Finland, but you can also find our dealers in Sweden and Norway.

Improve your workflow with the right transport solution

If you need a transport solution that is something out of the ordinary, Tyllis is a safe choice. We manufacture crane trucks, truck bodies, flatbeds, trailers, curtainsiders, dollies, semitrailers and more according to your needs and wishes.

You can always save time and money with a transport solution that facilitates the loading and unloading of goods. The driver’s work is also easier and more pleasant with appropriate equipment.

Invest in quality and save money

Quality is about details that make a difference. For you, it means a reliable and practical transport solution that stands the test of time and the road. For us, it’s about inventive designs, tight joints, carefully protected electrical cables, and a desire to make a product we can proudly put our name on.

Tyllis is an ISO 9001-certified company, so you can be sure that quality means as much to us as it does to you.

Smooth and personal contact for the best results

Your wishes are the raw material for product development. That’s why we want to make it easy for you to contact us during the planning and production of your transport solution.

Combine experience with modern technology

The experience of your work is the starting point. Combine your wishes with our 70 years of experience in manufacturing transport solutions, and you will get a great result. You can count on the design being roadworthy, lightweight and very durable.

History

1956–1970

The Tylli brothersIt was March 1956, Elvis Presley had just released his first record, Morocco had declared its independence, and Erik and Levi Tylli started doing repairs in their newly built workshop in Kokkola, Finland.

In the early years, the Tylli brothers offered service work, including repairs to agricultural machinery. This was strenuous blacksmithing work, but it gave the brothers practical skills that were very useful when they later moved on to developing their own products.

Their first original products were mainly flatbeds for Bedford and Gatz trucks. The bodies were made of wood, and all the locks and hinges were forged in the brothers’ workshop. Eventually, the brothers also started fitting Nummi’s tipping cylinders and cranes to various transport vehicles. The cooperation with Nummi was fruitful, and soon the brothers were also responsible for a spare parts warehouse for Nummi.

1971

Manufacturing takes overIn the early seventies, the time was ripe to expand the business, and a larger hall was built next to the old workshop. The Tylli brothers’ workshop now employed 5-6 people, and the company was entirely focused on in-house production.

1989

Generational shiftAfter 33 years of persistent metalwork, it was time for a generational change in the company. Three brothers and three cousins now took over responsibility for the business, and Göran Tylli was appointed CEO.

1992

A general partnershipIn 1992, the company form was changed to a general partnership, and the company was renamed Tyllis Verkstad, öppet bolag – Tyllin Korjaamo, avoin yhtiö.

1993

Tenants on NiittykatuThe business had grown and urgently needed more space. The dilemma was solved by renting painting facilities from Hartman Auto on Niittykatu in Kokkola.

1994

Limited liability companyThe corporate form was changed a second time when the company was registered as a limited liability company, Tyllis Verkstad Ab – Tyllin Korjaamo Oy.

1996

RelocationThe company bought a property on Niittykatu, and all production was moved from Kaustari.

1999

Blast hall builtA blast hall was constructed to further the manufacturing process.

2000

Fire and renovationThe new millennium got off to a rocky start for the company when a fire broke out in the production hall. During the subsequent renovation, both the office space and the production hall were enlarged. The company name was changed to Tyllis Oy Ab in the same year.

2001

New premisesThe renovated and newly built facilities were completed, and Tyllis rose from the ashes, stronger than ever.

2003

Property purchaseIt takes a lot of space to produce top-notch transport solutions. Tyllis needed more elbow room and decided to buy the neighbouring plot of land and its properties.

2004

ISO certificationTyllis obtained the ISO 9001:2000 quality certificate and the EN 729-3:1995 welding standard. The company employed 32 people at this time.

2005

New production hallA new production hall was completed in October, increasing the production space by 1,000 m2.

2006

Fiftieth anniversaryHip-hip-hooray! A real milestone was reached when Tyllis celebrated its 50th anniversary in March. The same month, a new 200 square metre paint booth was opened. The workforce now totalled 42 people.

2007

CNC machine acquiredA CNC plasma cutting machine was taken into use. The machine streamlined the process of cutting out high-precision sheet metal components for production.

2008

Space for future needsA growing business must always plan for the future. Tyllis, therefore, bought more land in the vicinity to make room for future expansion.

2011

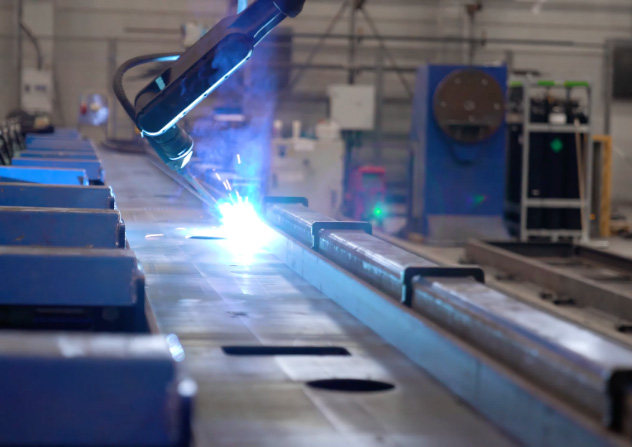

The welding robot arrivesMan and machine joined forces as Tyllis welcomed the first welding robot to their factory.

2016

Sixtieth anniversaryTime passes and before you know it, Tyllis is celebrating its 60th anniversary. The experience of the past years was put to good use when planning new production facilities.

2017

45 employeesThe factory was getting crowded. The steadily growing demand for Tyllis’s transport solutions once again required increased production capacity and more workspace. Therefore, the company started building new production facilities, another blast hall and a paint booth totalling 3,000 m2. The workforce now totalled about 45 people.

2018

New facilities are put into operationThe production facilities, which were under construction the previous year, now became operational.

2021

New generational shiftA new generational renewal took place in Tyllis’s management, and it was now time for the third generation to assume greater responsibility for the company’s future. In the same year, the old production hall received energy-efficient LED lighting and a much-needed facade renovation.

2022

Green energyTyllis went green and installed solar panels with a total peak power of 110 kW. Some operations were rationalised thanks to the purchase of a new and larger CNC plasma cutting machine.

WANT TO TRANSPORT SMARTER AND EASIER?

Don’t hesitate to get in touch. Together we will develop a cost-effective solution for your transport needs.